The company DELTA HL s.r.o. deals with manufacturing and assembling of all steel structures, mainly from high fine-grained steel (S690QL, S700MC, S890QL, S960QL). Major part of production is represented by jibs (arms) and lifting equipment.

Welding

We are welding by automated and manual technique MIG, MAG, TIG. We are certificated by DIN EN ISO 3834, part 2. for production of welded steel structures, ČSN EN 15.085 part 2. for chassis parts and other rail vehicle parts, and next ČSN EN 1090-2, EXC 3 for steel structures (previously DIN 18800 part 7, klas. E) for materials S235, S275, S460M, S700MC, S690QL, S890QL, S960QL. Robotic welding enables us placing the weldment of 14 m length and 4 m rotational diameter. For reparation purposes we have verified technique of welding and hard metal welding deposits of parts, that are high-stressed by abrasive wear and impacts. (Hardox 400HB to 600HB).

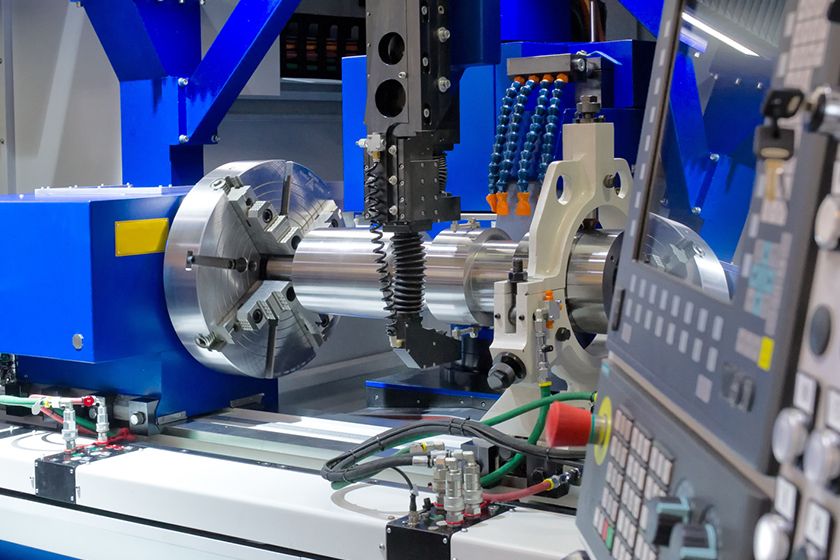

CNC machinig

We perform CNC machining – milling, turning and precision machining by using of 3 to 6 axis CNC machines. Those machines are programmed by our engineers in 3D CAD/CAM software. Flexibility and possibility of machining big and heavy parts up to 14 m length and 24 tons weight is our advantage in this range.